Traceable 3D Target-based Laser Scanning

The benchmark in target-based 3D reality capture.

FARO’s Traceable 3D Target-based Laser Scanning sets the global benchmark for precision reality capture — delivering unmatched accuracy and repeatability through the powerful Traceable 3D Reference System.

Over the past few decades, 3D reality capture has become the go-to method for documenting the as-built condition of physical assets. By converting millions of data points into precise 3D point clouds, it creates a virtual model that mirrors reality with impressive accuracy.

However, even smaller projects can produce hundreds — sometimes thousands — of individual scans, all of which need to be registered and aligned. And it’s not just a one-time task. These processes must be repeated throughout an asset’s lifecycle. That’s where traditional cloud-to-cloud or target-less registration methods can struggle — especially when consistent accuracy across multiple scans is critical.

Traceable 3D solves this challenge by breaking down data silos and unifying all scans into a single, reliable coordinate system. Using specialized mounted targets, it creates fixed yet re-positionable anchor points that enable accurate, repeatable scan alignment — ensuring that even the subtlest changes in your asset are captured over time.

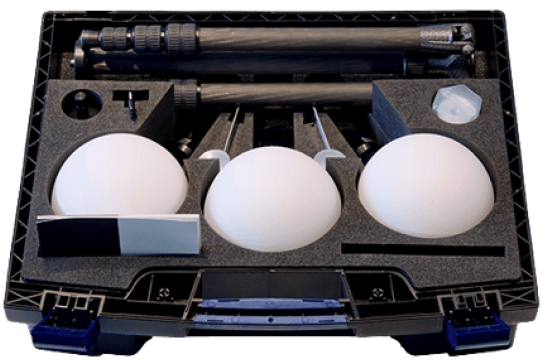

A Complete and Calibrated Reference System

FARO’s Traceable 3D is more than a method — it’s a full ecosystem of precision-calibrated accessories designed for total compatibility and performance. Over 35 new tools have been added to the lineup, including large and medium-sized spheres, flat targets, high-precision mounts, quick-release tripods, and magnetic bases for both flat and curved steel surfaces. All components are manufactured to FARO’s exacting standards to ensure seamless integration and flawless repeatability.

Business Value of Traceable 3D

Elevate productivity, accuracy, and collaboration across your entire project lifecycle.

- Save Time and Maximize Productivity

Traceable 3D seamlessly integrates with all major surveying, scanning, and metrology tools, helping teams move faster while staying precise. As the demand for 3D scanning grows, reference points can be positioned in advance and updated automatically as new scans are added — capturing even the smallest design changes in real time. The result? Stakeholders gain continuous visibility into evolving site conditions, while data from the field is quickly processed, analyzed, and synchronized into actionable insights. - High Accuracy. Reliable, Repeatable Results.

Built for demanding environments, the Traceable 3D Reference System includes a powerful set of target accessories that enable high-precision, repeatable scans — even in tight spaces or areas with minimal scan overlap. Whether it’s stairwells, mechanical rooms, or large industrial zones, you can rely on permanent target mounts that serve as consistent benchmarks. Magnetically mounted prisms and other flexible tools extend scanning options without compromising on accuracy. - Designed for Multimodal Use

Traceable 3D isn’t limited to 3D laser scanners. The same mounted targets and accessories can be used across a range of measurement tools — from laser projectors and trackers to portable arms and total stations. This versatility allows teams to collect, align, and compare data with different hardware across the lifecycle of any physical asset. - Reusable, Incremental Data

Because all targeted data is collected within a unified coordinate system, the information remains compatible across time, devices, and workflows. As structures evolve — inside and out — data can be re-used and expanded upon rather than recreated from scratch. You gain a continuously updated 3D model that supports collaboration, oversight, and informed decision-making. - Geo-Precision with Real-World Alignment

Mounted rectangular and spherical targets act as geo-referenced anchors, bringing scanned data into real-world context with mapping or GIS platforms. This geographic accuracy is especially valuable for tracking construction progress, monitoring structural shifts, or overseeing large-scale projects where precision is critical.

When Cloud-to-Cloud Isn’t Enough

While cloud-to-cloud registration has its uses, it can fall short in large-scale or complex environments — especially where geo-referencing is essential or scan overlap is limited. Traceable 3D enhances and surpasses traditional scanning workflows, offering operators the ability to place physical targets, scan repeatedly, and confidently register point clouds with precision.

This is a game-changer for survey control in tunnel construction, automotive facilities, and manufacturing plants where overlapping scans can be difficult and small data gaps affect modeling. The same applies in environments with repetitive features — stairwells, pipelines, boiler rooms, or long corridors — where cloud-only workflows often lead to registration errors or time-consuming rework.

By combining target-based scanning with hardware that’s built for repeatability, Traceable 3D gives professionals complete confidence in every scan — supporting long-term asset tracking, compliance, and detailed analysis.

A Repeatable Workflow That Scales

Traceable 3D® Target-Based Laser Scanning supports three key workflows for continuous, high-precision measurement:

- Pre-set Infrastructure

Install permanent target mounts throughout your facility — on walls, floors, or even machinery — to build a fixed reference system for scanning. - Capture Your Data

Attach your capture device to the targets and begin scanning. Different teams (BIM, MEP, reverse engineering, line planning, etc.) can all contribute with consistent results, using the same coordinate system. - Update Your Digital Twin and Collaborate

Import the data into your system, refresh your digital twin, and share with stakeholders. With accurate, up-to-date 3D data, teams make smarter decisions faster, improving efficiency and project outcomes.

Features

Below, you will find the main features of the product.

Guaranteed Calibrated Accuracy

Each target in the Traceable 3D system is professionally calibrated and traceable, delivering verified accuracy within 1mm. This ensures your scan data remains consistent, reusable, and reliable—no matter when or how often it's captured. The structured data format makes it easy to share and export across platforms and with all project stakeholders.

Seamless Integration Across Devices

Traceable 3D is built to work flawlessly with all major scanning, surveying, and metrology tools—ensuring compatibility even in scenarios where cloud-to-cloud registration struggles. Whether you're working in complex environments or need highly accurate results, the system brings consistent performance across all your hardware.

Guided by Industry Experts

Gain confidence in your reality capture workflow with direct access to Traceable 3D specialists. Our experts help you navigate technical questions, toolkit selection, and pricing options, ensuring you get the right setup for your specific application—from planning to execution.

Applications

Discover the applications in which the product can be used.

As-Built Documentation

Terrain Scanning

Industrial Scanning

Multimedia

Below you will find all available multimedia, including videos & images.

Testimonials

Read what our satisfied customers have to say.

Related Products

See related products from this manufacturer

Get a Quote

You can fill out the contact form below and one of our representatives will contact you shortly.