Manufacturing

Artec 3D scanners for manufacturing

From concept to actualization, Artec 3D scanners will transform your workflow across the entire manufacturing process. Artec 3D scanners are industry-leading precision instruments that play crucial roles in a variety of processes in industrial design and manufacturing.

From product development to manufacturing, our high-precision 3D scanning solutions cut the time and cost of capturing object data. Highly accurate scan data improves the reliability of processes, and seamless compatibility with a variety of widely used CAD and CAM programs allows you to deploy them in quality control, reverse engineering, and many more manufacturing-related use cases.

Benefits

- 9x faster than a CMM

An Artec scanner takes one second to capture up to 35 million points. A CMM needs hours to capture a few hundred. - 0.01 mm max accuracy

Artec 3D scanners work without targets and are precise to fractions of a millimeter. Our desktop 3D scanner achieves accuracy as high as 10 microns. - <2h for training

Artec scanners are designed to be intuitive, versatile, and easy to use. You’ll be confidently scanning in under 2 hours! - 85% savings in time and cost

Just by using Artec scanners, an international manufacturer and distributor of construction machine spare parts saves 85 percent in time and cost.

Applications

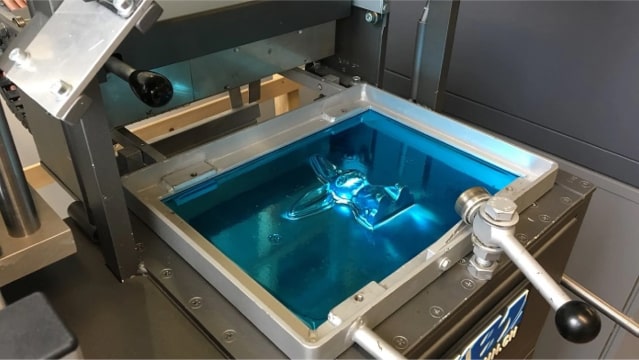

- Rapid prototyping

Cut down on the time it takes to get from design to production using precise, high-resolution 3D models of prototypes to quickly and easily test your designs. - Inspection and quality control

Reduce time-to-market by optimizing the quality control process. Get accurate 3D models in minutes, which you can compare to CAD designs. - Reverse engineering

Fabricate parts with missing documentation, integrate existing products into your design process, or recreate legacy designs easily without needing to take manual measurements. - Drastically reduce lead times

By using 3D scanning methods, companies have reported reducing lead times in production processes like packaging by as much as 20 times. - Additive manufacturing

Go beyond conventional manufacturing techniques and use the flexibility of additive manufacturing to bring previously impossible design concepts to life.

Related Products

See related products from this manufacturer

Get a Quote

You can fill out the contact form below and one of our representatives will contact you shortly.